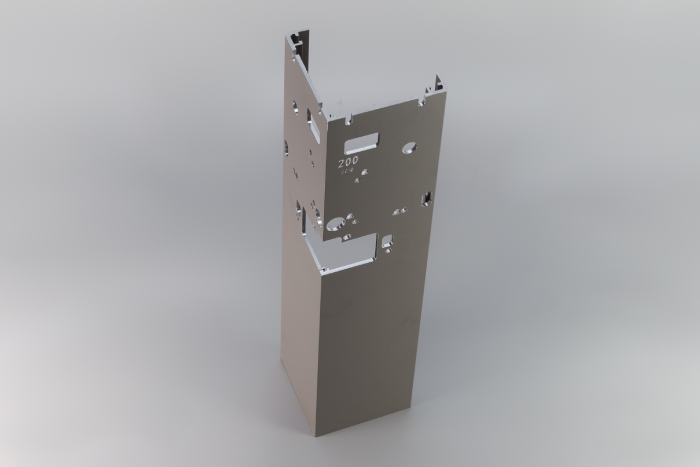

Aluminum profile machining

Machining involves employing appropriate machines that utilize aluminum ductility and give it the ultimate and desired shape by removing excess material through the cutting and grinding method.

Exlabesa has 34 3-, 4- and 5-axis 3D mechanical machining stations that ensure machining with an accuracy of ±0.05 mm, with a maximum profile length up to 21 000 mm. These stations provide different machining types: punching, milling, deburring, vibrating, precision cutting, drilling, plasticizing, threading, etc.

Such possibilities allows us to offer high flexibility in the case of mechanical machining of all kinds of aluminum profiles, while ensuring maximum manufacturing precision.

We also own various high-precision saws, with a cutting tolerance ±0.5 mm and slope tolerance of 1º.

34 machining stations

Maximum capabilities: X: 21 000 mm, Y: 600 mm, Z: 310 mm

Cutting tolerance ±0.5 mm and slope tolerance 1º

C axis pitch: -90º 0 +90º

Palpation (contact) testing system: Renishaw

CNC-controlled hydraulic cutting discs for external dimensions up to 415 x 274 mm