RE-local: Recycled Low Carbon Aluminium

Boosting circular industry

Recycled Low Carbon Aluminium

Aluminium is crucial for a circular industry. It has even been designated as a strategic material by the European Union due to its exceptional qualities (lightness, durability or resistance, among others), notably its infinite capacity for recycling, which eliminates the need to extract new mineral and drastically reduces energy consumption and CO2 emissions.

Exlabesa’s recycling process ranges from collection and smelting to the extrusion of new profiles. This way we promote a cleaner, more efficient and sustainable industry, contributing to the achievement of the objectives of the European Green Deal regarding the decarbonisation of industry. The goal: to achieve a global economy with low emissions and environmentally friendly.

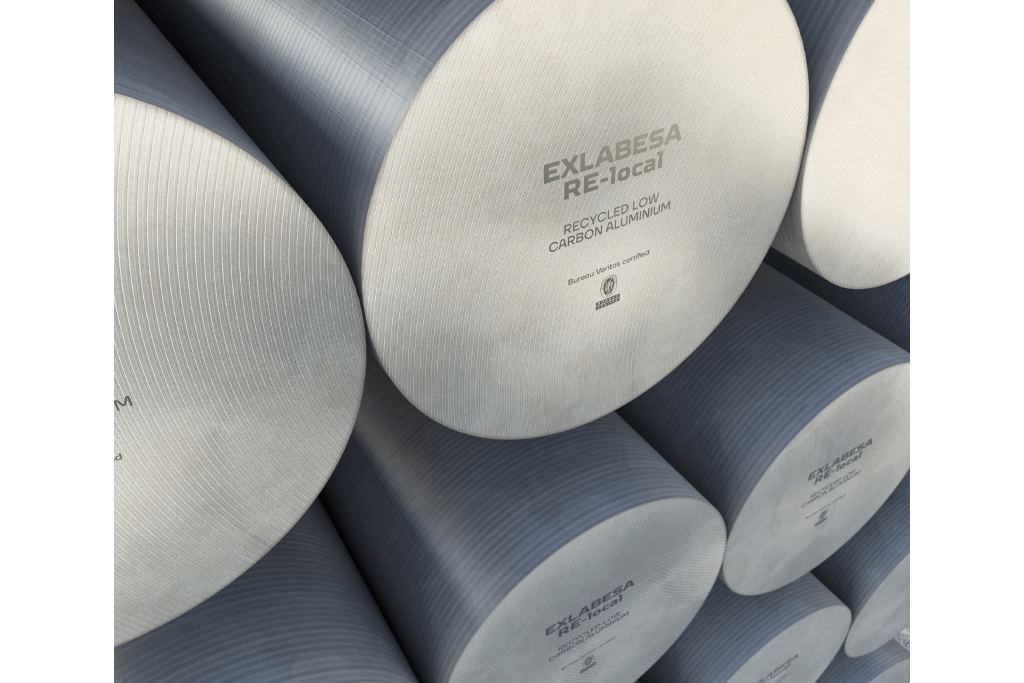

Certified recycled aluminium

Exlabesa’s RE-local billet has a carbon footprint of only

2.95 kgCO2 eq per kg of aluminium, verified by Bureau Veritas

according to the ISO 14067: Product Carbon Footprint (PCF) standard.

Our aluminium recycling process

1 COLLECTION

Aluminium collected both from third parties and from our own factories

2 CLASSIFICATION

It is separated according to its alloy to preserve its mechanical characteristics

3 FOUNDRY

After organizing them in packages, they are melted at 750ºC to create a new billet of aluminium

4 EXTRUSION

With the billet obtained in the foundry, new aluminium profiles are extruded

5 COMMERCIALISATION

These profiles are used by different types of industries for the production

6 USE

The final products are used. Then, the recyling process can start again

EXLABESA RE-LOCAL

RECYCLED LOW CARBON ALUMINIUM

95%

Reduction of energy consumption

2,95 kg of CO2

Per kg of aluminium

82%

Reduction of the carbon footprint