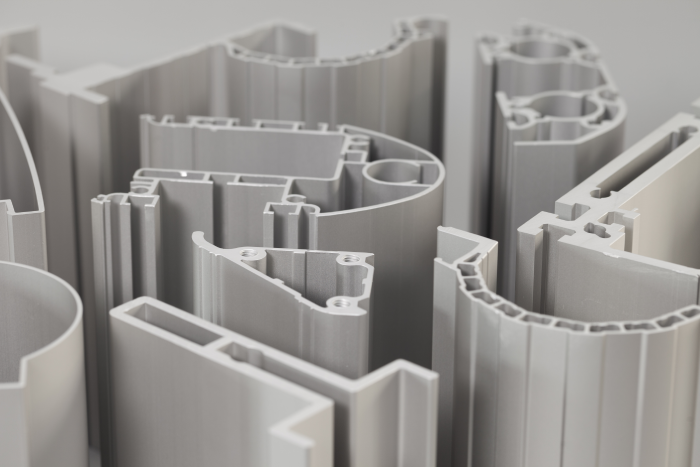

Extrusion

Aluminium extrusion is a mechanical process that involves converting large, solid blocks of various alloys into long profiles of specific cross-section. The raw material is heated and piston-pressed via a hardened-steel die, with a centrally located holed giving the profile its shape.

After the process, the product is stretched, cut and cooled, which are required to obtain the desired strength and stiffness of the final product.

Exlabesa currently owns 33 extrusion presses with a pressure force ranging from 13 MN to 85 MN. Such capabilities position us at the global forefront of the industry and enable satisfying the demand for extruded aluminium in all its applications, enabling us to manufacture profiles fully tailored to the needs of the clients and every project. This is topped up with high flexibility and dynamics of our manufacturing system, which allowed us to achieve our manufacturing capabilities of 300 000 tons per year.

33 extrusion presses with a pressure force ranging from 13 MN to 85 MN.

Alloys: 1070A, 3XXX, 5XXX, 6005, 6060, 6061, 6063, 6082, 6101, 6106, 6463, 7003 and 7020.

Maximum extruded profile length: 28 000 mm.

Annual manufacturing capacity: 300 000 Tm.

Diameter: from 8 mm to a maximum of 700 mm.

Standardized profiles.

Maximum profile weight: up to 120 kg/m.