Exlabesa installs a new state-of-the-art vertical coating plant

At Exlabesa, a benchmark in the extrusion of high added value aluminium profiles for architecture and industry in general, we have increased our production capacities with the installation of a new state-of-the-art vertical coating plant at our factory in Padrón (Spain), which is the company’s 7th plant.

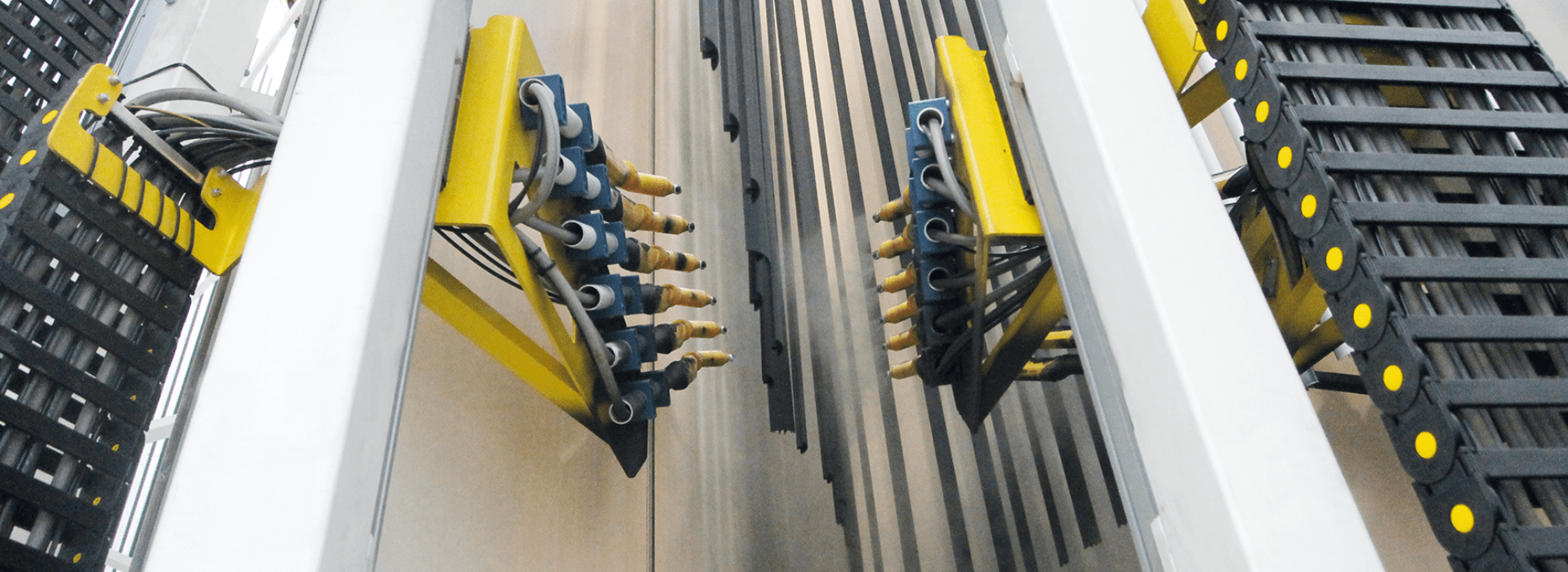

This new installation is state-of-the-art, equipped with 2 V-Shape powder coating booths with a high transfer performance and an operating speed of 2.2 metres/minute. In addition, it achieves a productivity of 3 tonnes/hour and has the capacity to process profiles up to 8 metres in length.

“2 V-Shape booths”

An advanced, automated and complete system that allows us to continue to anticipate the needs of the market in the face of the growing demand for this treatment, to which we also respond with a catalogue of finishes with an infinite number of possibilities. We also guarantee the best results in the lacquering process through the Qualicoat-Seaside label quality certification.

The constant investment in state-of-the-art machinery, such as this new lacquering plant, reaffirms Exlabesa’s competitiveness on an international level, being able to carry out any type of project with reliability, speed and total creative freedom.