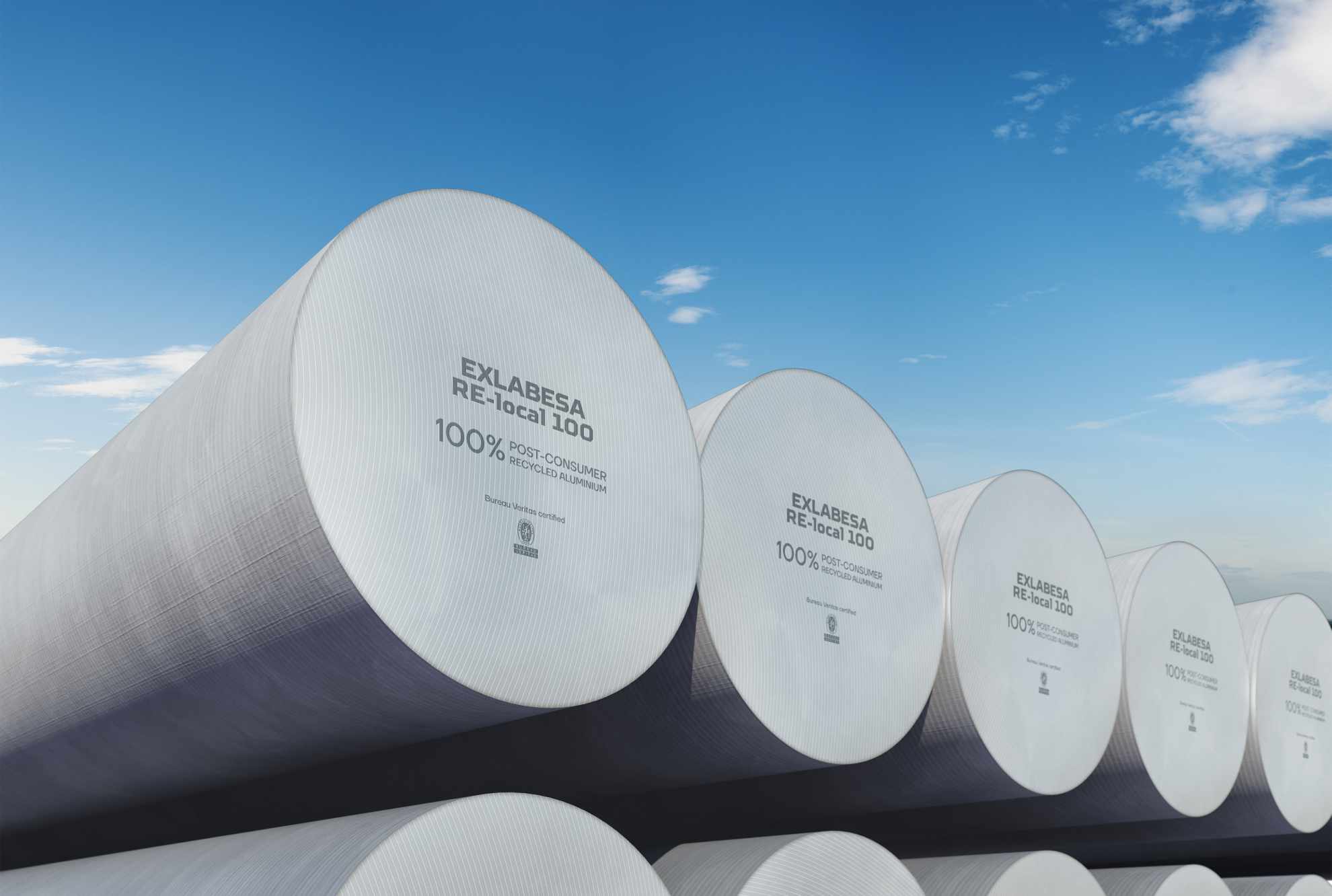

RE-local 100: 100% post-consumer recycled aluminium

EXLABESA RE-local 100

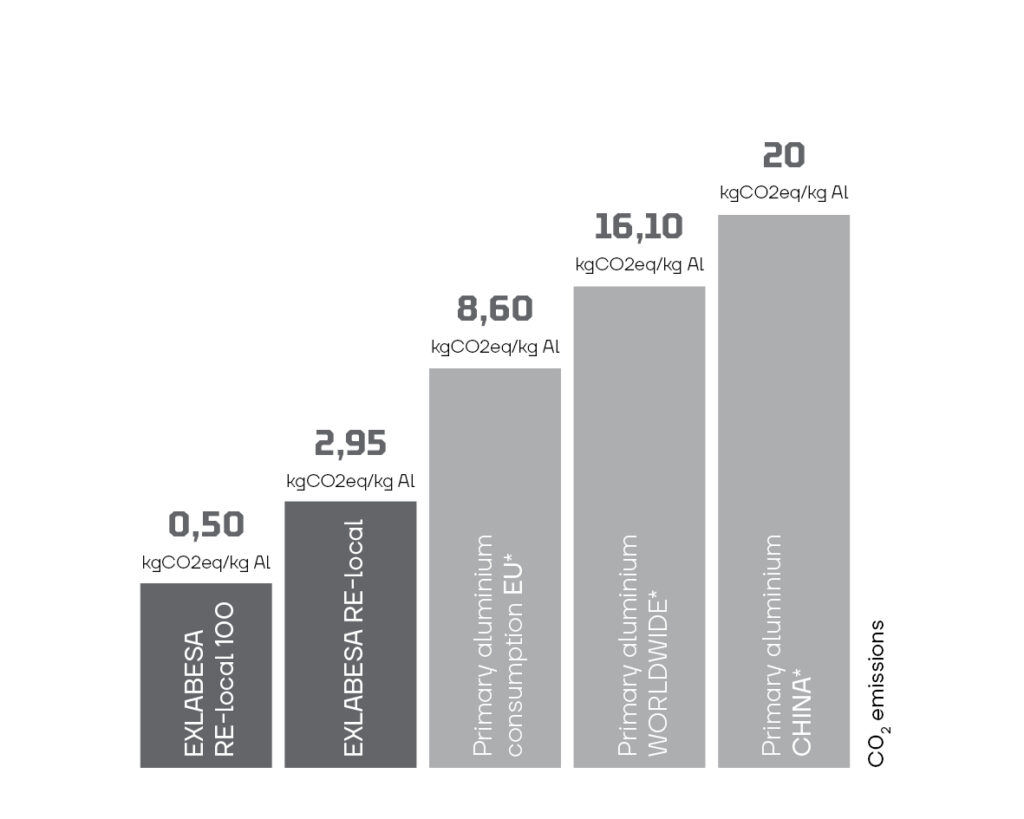

100% post-consumer recycled aluminium with near-zero carbon footprint

With RE-local 100, Exlabesa’s 100% post-consumer verified recycled aluminium, we position ourselves as leaders in the decarbonisation of the construction industry, promoting circular and more sustainable architecture.

RE-local 100 is produced entirely from scrap from products that have reached their end of life, thus promoting the circularity of aluminium, an infinitely recyclable material.

Aluminium is essential to meeting the objectives of the European Union’s Green Pact, which aims to reduce carbon emissions to climate neutrality by 2050. It is also a strategic raw material in the EU’s Key Raw Materials Act because of its key role in the transition to a sustainable economy.

An infinite cycle

1 COLLECTION

Aluminium collected both from third parties and from our own factories

2 CLASSIFCATION

It is separated according to its alloy to preserve its mechanical characteristics

3 FOUNDRY

After organizing them in packages, they are melted at 750ºC to create a new billet of aluminium

4 EXTRUSION

With the billet obtained in the foundry, new aluminium profiles are extruded

5 COMMERCIALISATION

These profiles are used by different types of industries for the production

6 USE

The final products are used. Then, the recyling process can start again

Post-consumer aluminium recycling

Recycling gives aluminium an infinite life and reduces CO2 emissions

Aluminium has the exceptional capacity to be 100% recyclable unlimited times without losing its quality or properties. Exlabesa’s recycling process ranges from collection and smelting to the extrusion of new profiles. In this way, we promote a cleaner, more efficient and sustainable industry, contributing to the achievement of the European Green Pact’s objectives regarding industrial decarbonisation. The goal: to achieve a global economy with low emissions and respect for the environment.

Foundry

We operate several state-of-the-art recycling centres

Our foundries produce more than 80 000 tonnes of recycled billet per year, the equivalent of the aluminium needed to equip more than 660 000 average homes, almost six times the number of new construction projects approved in Spain*. These unique capabilities allow us to take on any industrial challenge and meet the most demanding projects.

*108 895 new building licenses in 2022 according to data from the Spanish Ministry of Transport, Mobility and Urban Agenda.

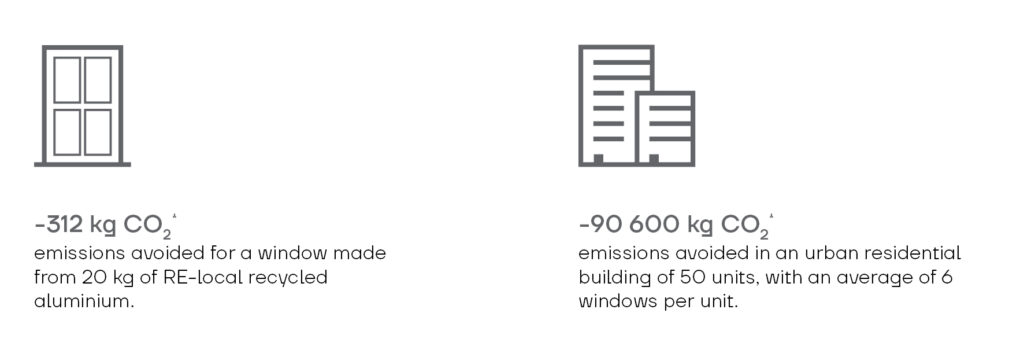

Recycled aluminium for a sustainable and circular edification

Aluminium is a key material for building decarbonisation

The building sector is responsible for more than 36% of greenhouse gases, of which 28% is embedded carbon (generated in the construction and renovation phase). Recycled aluminium is a key material for the future of this industry as it not only eliminates the need to mine new aluminium but also drastically reduces energy consumption and CO2 emissions.

Reduce the environmental impact of your project with RE-local 100 recycled aluminium

RE-local 100 recycled aluminium is incorporated into our production process to manufacture door,

window and enclosure profiles. In this way, we contribute to the building

value chain with sustainable solutions that allow us to respond to the

growing market demands and facilitate obtaining the most demanding

environmental certifications such as LEED, BREEAM or VERDE.

*Source: International Aluminium Institute and European Aluminium Association